MgSo4 Sanding Board

It made from magnesium oxide (Mgo), magnesium sulfate (Mgso4), bamboo filler and reinforced by fiber glass mesh.

Sanded Mgo board surface is by sanded treatment, which made it smoother and flatter, the thickness is more accurate. It has the characteristics of A1 class fire rated, price flatness, dimension stable and environmental protection, specialized used as the core or underlay material of composite Board and flooring.

We can provide UV sealing process for better adhesive fusion.

Sanded Mgo board surface is by sanded treatment, which made it smoother and flatter, the thickness is more accurate. It has the characteristics of A1 class fire rated, price flatness, dimension stable and environmental protection, specialized used as the core or underlay material of composite Board and flooring.

We can provide UV sealing process for better adhesive fusion.

Specification

| Product | Substrate Sanded Mgso4 Board |

| Brand | OCM |

| Basic Compounds | (MgO)+(Mgso4s)+(glass fibre)+(Bamboo fibre) |

| LENGTH | 8 ft(2440mm) Customized |

| WIDTH | 4 ft(1220mm) Customized |

| THICKNESS | 4 5 6 8 10mm if other requested |

| USE | Substrate for decorative board. |

| Color | Grey and White |

| Surface texture | One sanded or two sanded. One polish. |

| Edges | Square |

| Density | 1.1-1.2T/M3 |

| Combustibility / Fire Ratings | non-combustible / A1 |

| Moisture content | ≤8% |

| Bending Strength | ≥20-30Mpa |

| Impact Strength | > 9kJ/m2 |

| Modulus of elasticity | ≥5000Mpa |

| Dry Shrinkage | ≤0.3% |

| Wet Expansion Rate | ≤0.3% |

| Thermal Conductivity | ~0.44 W / mK |

| Thermal Expansion Hot/Cold | 0,01 mm/mC (from temp +20C to -20C) |

| Surface Alkalinity | 8-10 Ph |

| Asbestos Analysis | Absent – not measurable |

| Formaldehyde Analysis | Absent – not measurable |

| TVOC-ASTM D5116-10 | Below measurable levels of test instruments |

| Surface /Internal bonding strength | ≥1.3MPa |

| Chloride ion content-ASTMC 871-11 | 0.012% |

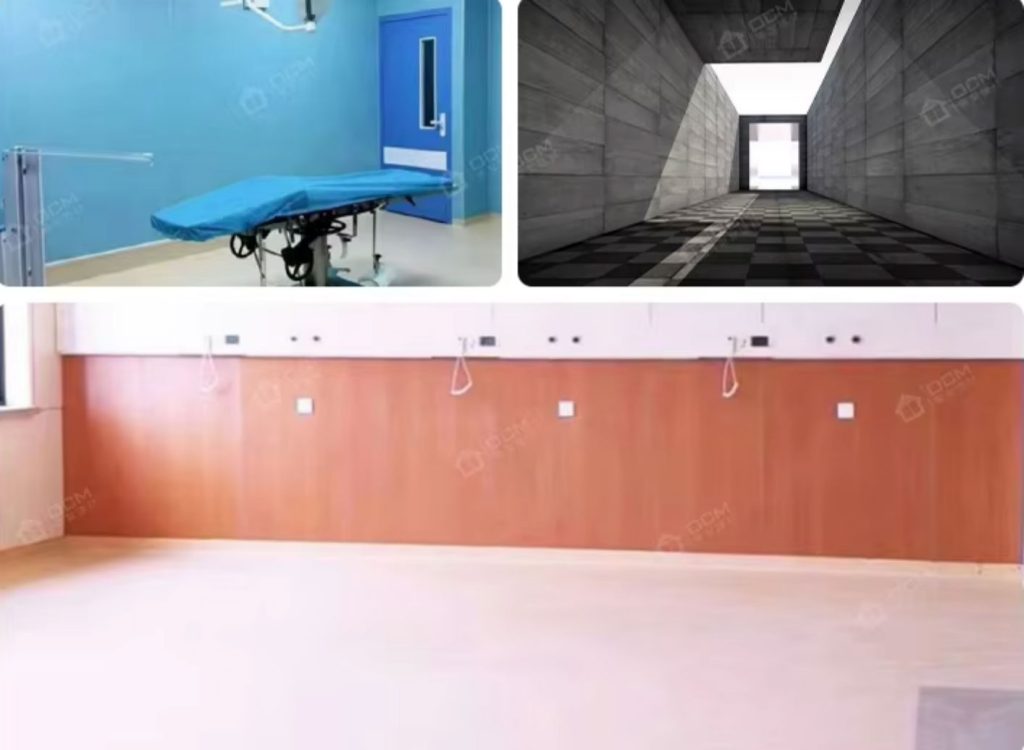

Application

Core for Composite flooring, Substrate for decorative board, Furniture base /substrate board.